From Data to Action: How Analytics Improve Manufacturing Efficiency

Unlocking the Power of Factory Data to Drive Smarter, Leaner Operations

In today’s fast-paced manufacturing world, data is everywhere: flowing from machines, sensors, supply chains, and enterprise systems. However, having data is not enough. The real value lies in how it is used. This article explores how manufacturers can transform raw data into actionable insights that improve processes, reduce waste, and boost overall efficiency.

Whether you are already onboarding our products and looking to deepen your understanding, or you are exploring digital transformation for the first time, this article offers practical insights into how analytics can reshape your operations.

Why Data Is the New Engine of Manufacturing Excellence

Manufacturing has always been built on foundational pillars like autonomous robotics, system integration, and real-time data—core elements of Industry 4.0. In the age of the industry 4.0, these pillars are increasingly empowered and accelerated by various kinds of data stored in the integrated digital platforms. Every machine cycle, material movement, and operator input generate valuable information. When captured and analyzed effectively, this data becomes a strategic tool for continuous improvement.

Factories that embrace analytics move beyond reactive problem-solving. Instead of waiting for issues to surface, they anticipate them. Instead of relying on gut instinct, they make decisions based on evidence.

This shift from reactive to proactive operations is at the heart of modern manufacturing efficiency.

The Analytics Advantage: Turning Complexity into Clarity

Modern manufacturing environments are complex. Multiple systems, departments, and workflows interact in real time. Analytics help simplify this complexity by revealing patterns, trends, and anomalies that would otherwise go unnoticed. Here is how analytics drives efficiency across key areas:

Whether you are already onboarding our products and looking to deepen your understanding, or you are exploring digital transformation for the first time, this article offers practical insights into how analytics can reshape your operations.

- Process Optimization: By analyzing cycle times, material flow, and resource utilization, manufacturers can identify bottlenecks and streamline operations

- Quality Assurance: Machine learning models detect defects early, reducing rework and improving product consistency

- Energy Management: Real-time monitoring of energy consumption helps pinpoint inefficiencies and reduce costs

- Inventory Control: Predictive analytics align inventory levels with actual demand, minimizing overstock and shortages

- Workforce Productivity: Data on task completion and equipment usage helps managers allocate resources more effectively

These improvements are not theoretical, but they translate into measurable gains in throughput, cost savings, and customer satisfaction.

Real-Time Visibility: The Foundation of Agile Manufacturing

One of the most transformative aspects of analytics in manufacturing is the ability to see what is happening on the factory floor as it happens. Real-time visibility turns data into a dynamic, decision-making tool: giving teams the power to act, not just observe.

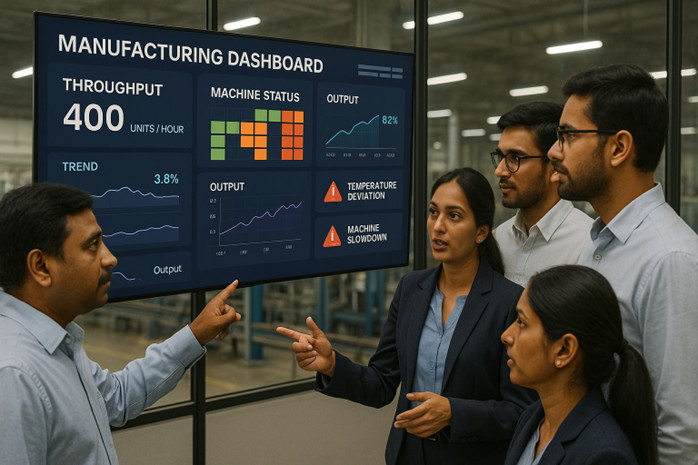

At the heart of this capability are centralized dashboards that aggregate live data from machines, warehouses, suppliers, and even external logistics partners. These dashboards do not just display numbers, they visualize performance trends, highlight anomalies, and provide context for operational decisions. For example, a sudden drop in machine throughput can trigger an alert, prompting maintenance teams to investigate before a breakdown occurs. Alerts and notifications are another critical component. These systems proactively inform teams of potential issues, such as temperature deviations in sensitive processes, delays in material delivery, or unexpected inventory shortages. Instead of discovering problems after they have caused disruption, teams can respond immediately, minimizing downtime and maintaining workflow continuity.

Visual analytics tools enhance this further by making complex data intuitive. Heat maps, trend lines, and interactive charts allow users to explore performance metrics without needing advanced technical skills. This democratizes data access, enabling frontline workers and managers alike to make informed decisions.

Real-time visibility empowers teams to:

- Make faster decisions: With live data at their fingertips, managers can adjust schedules, reallocate resources, or resolve issues without delay

- Coordinate across departments: Shared dashboards ensure that production, logistics, and quality teams are aligned, reducing miscommunication and improving responsiveness

- Respond to disruptions with agility: Whether it is a supply chain delay or a machine fault, real-time insights enable quick pivots and contingency planning

- Maintain consistent quality and performance: Continuous monitoring ensures that deviations are caught early, preserving product standards and customer satisfaction

Ultimately, real-time visibility is not just about having data, but it is about having clarity, confidence, and control. It transforms manufacturing from a reactive process into a proactive, agile operation where every decision is informed, every action is timely, and every team is empowered.

From Insight to Action: Embedding Analytics into Daily Workflows

The true power of analytics lies in its ability to drive action. Insights must be embedded into daily routines, not just reviewed in monthly reports.

When analytics becomes part of the workflow, teams can:

- Adjust production schedules based on live demand data

- Perform predictive maintenance to avoid costly downtime

- Optimize supply chain coordination in response to real-time conditions

- Continuously improving processes with measurable feedback loops This creates a culture of data-driven decision-making, where every improvement is backed by evidence and every team member is empowered to contribute.

Empowering People with Data: Building a Culture of Analytical Thinking

While technology plays a central role in transforming manufacturing, its full potential is only realized when people are empowered to use it effectively. Analytics is not just for data scientists or IT teams, but it is a tool for everyone on the factory floor, from operators to supervisors to plant managers.

Creating a culture of analytical thinking means giving teams the skills, tools, and confidence to interpret data and act on it. This involves:

- Training and Upskilling: Providing hands-on learning opportunities that teach employees how to read dashboards, understand KPIs, and use analytics tools in their daily work

- Accessible Interfaces: Designing user-friendly systems that make data intuitive and actionable, even for non-technical users

- Collaborative Problem-Solving: Encouraging cross-functional teams to use data as a common language for identifying issues and proposing solutions

- Recognition and Feedback: Celebrating data-driven improvements and sharing success stories to reinforce the value of analytics

When employees feel ownership over the data they use, they become more engaged, proactive, and innovative. This shift turns analytics from a back-office function into a frontline capability, one that drives continuous improvement and operational excellence.

Moreover, empowering people with data helps bridge the gap between strategy and execution. It ensures that insights do not just stay in reports but translate into real-world actions that improve performance, reduce waste, and enhance responsiveness.

Your Next Step: Start Small, Scale Smart

You do not need a massive overhaul to begin. Start with one process, perhaps a production line, inventory system, or maintenance schedule.

- Collect data

- Apply analytics

- Measure the impact

- Share the results

- Then expand

Analytics is not just a tool, but it is a mindset. It is about curiosity, experimentation, and continuous learning. And it is accessible to any manufacturer willing to take the first step.

Contact Us

Email us at ap_diin_msdsales@ap.denso.com ; Call us at +91 9980445746;

Explore more

Why Carbon Footprint Management is Becoming a Business Imperative

Manufacturers are at the forefront of the global effort to reduce carbon emissions. What was once a voluntary sustainability initiative has evolved into a non-negotiable business requirement. Today, managing carbon emissions is not optional—it is a strategic necessity that directly influences market access, brand equity, and long-term business resilience.

The Basics of Vehicle Digital Inspection: What It Is and How It Works

Discover how digital transformation is revolutionizing vehicle inspection processes, improving efficiency, accuracy, and compliance while reducing costs and environmental impact.

How Carbon Footprint Management Drives Corporate Financial Performance

How Carbon Footprint Management Drives Corporate Financial Performance